Introduction to PU Sandwich Panels

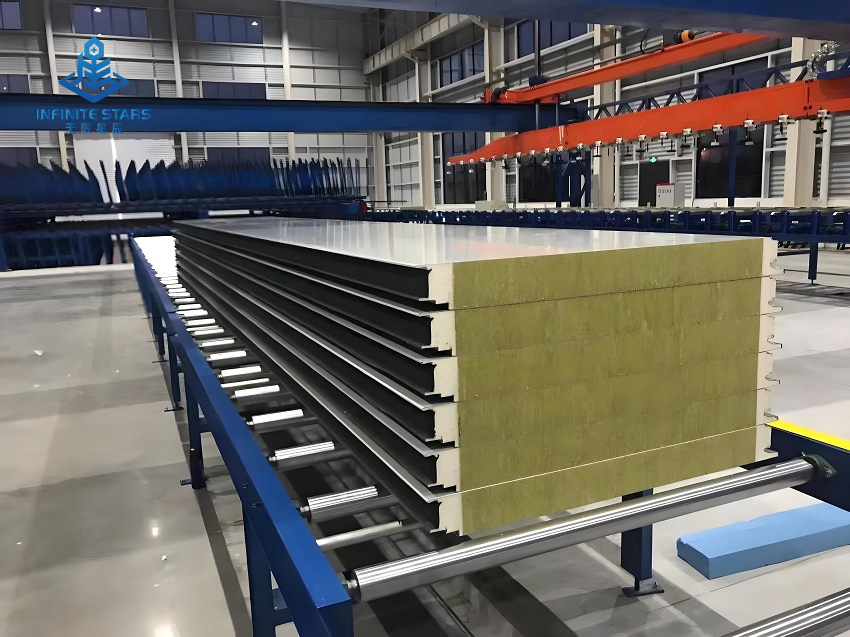

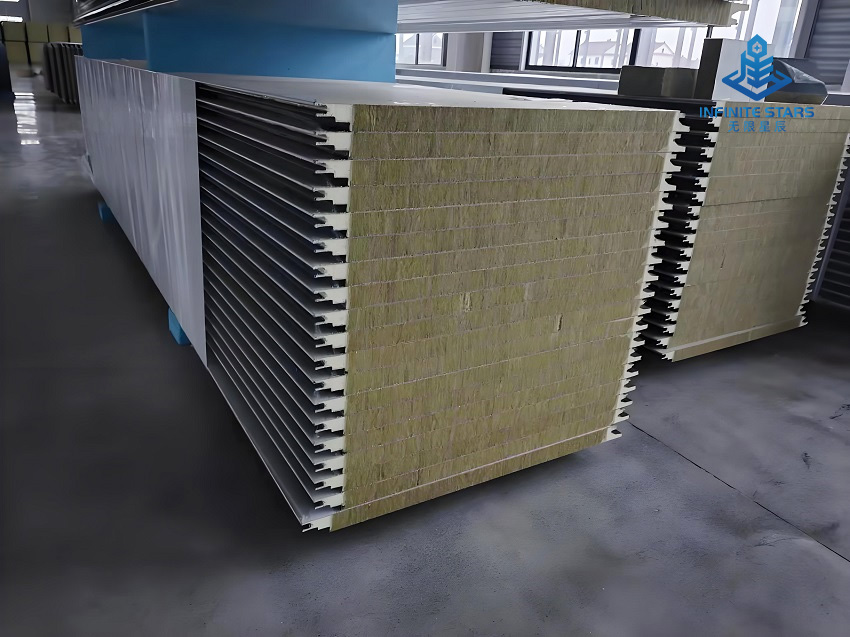

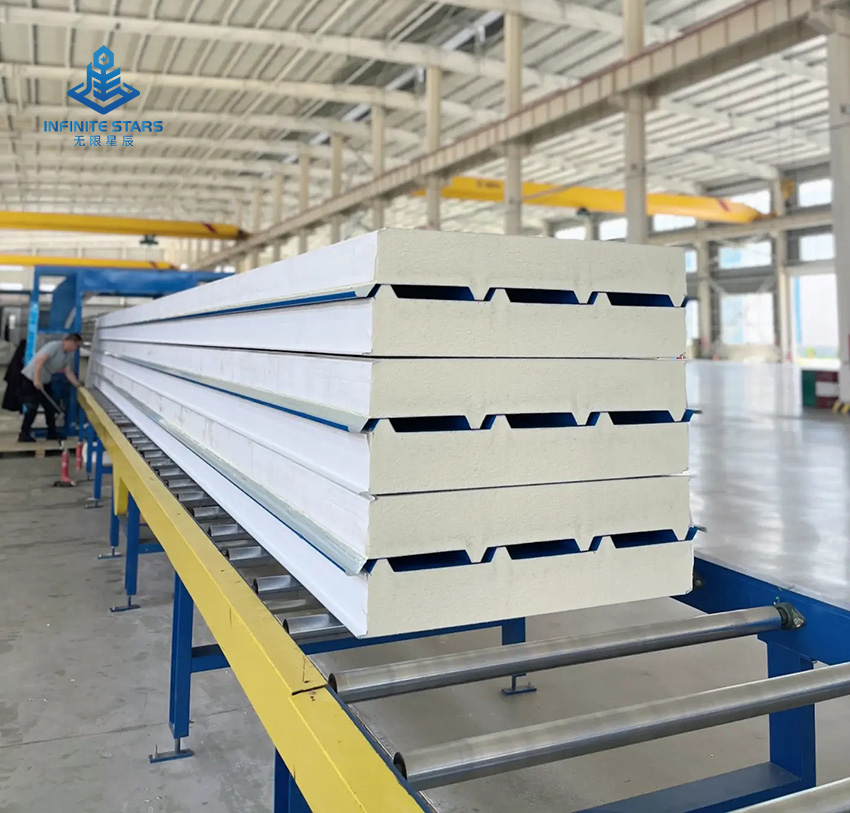

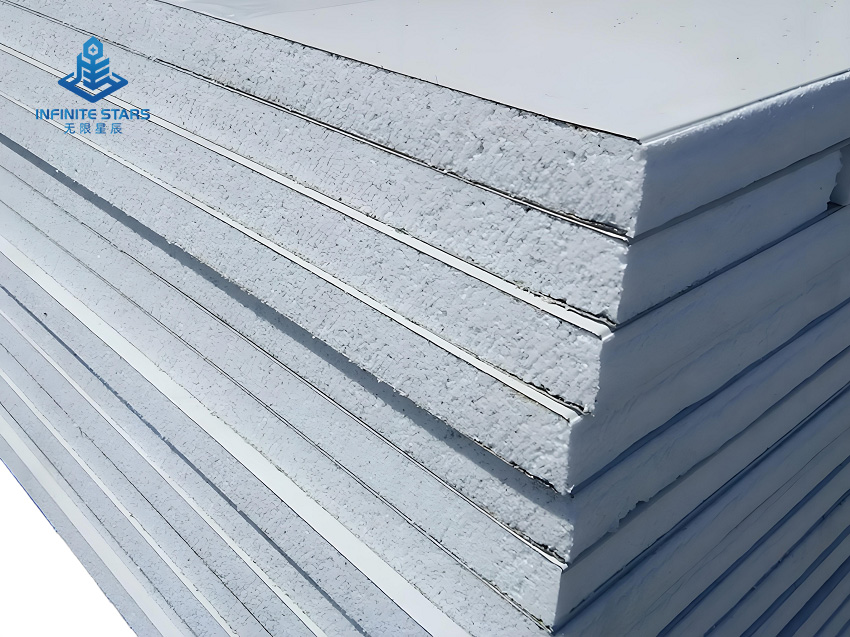

1. Structure and Composition

Facing Layers: Typically metal sheets (e.g., color-coated steel, stainless steel, aluminum, galvanized steel) or non-metal sheets (e.g., gypsum board, cement fiberboard).

Core Material: Rigid polyurethane foam (PU), injected between the panels under high pressure to form a tightly bonded structure.

Thickness: Usually 50–200 mm, customizable based on requirements.

2. Key Features

High Thermal Insulation: Low thermal conductivity (0.022–0.028 W/(m·K)), outperforming materials like rock wool and EPS.

Fire Resistance: Typically rated B1 (flame-retardant), with some treated versions achieving A2 (non-combustible).

Lightweight & High Strength: Density ~30–50 kg/m³, reducing structural load while maintaining strong compression/flexural strength.

Waterproof & Moisture-Resistant: Closed-cell rate ≥90%, preventing water vapor penetration.

Eco-Friendly: Some products use fluorine-free foaming technology, complying with green building standards.

Easy Installation: Can be cut, drilled, and installed quickly with modular construction.

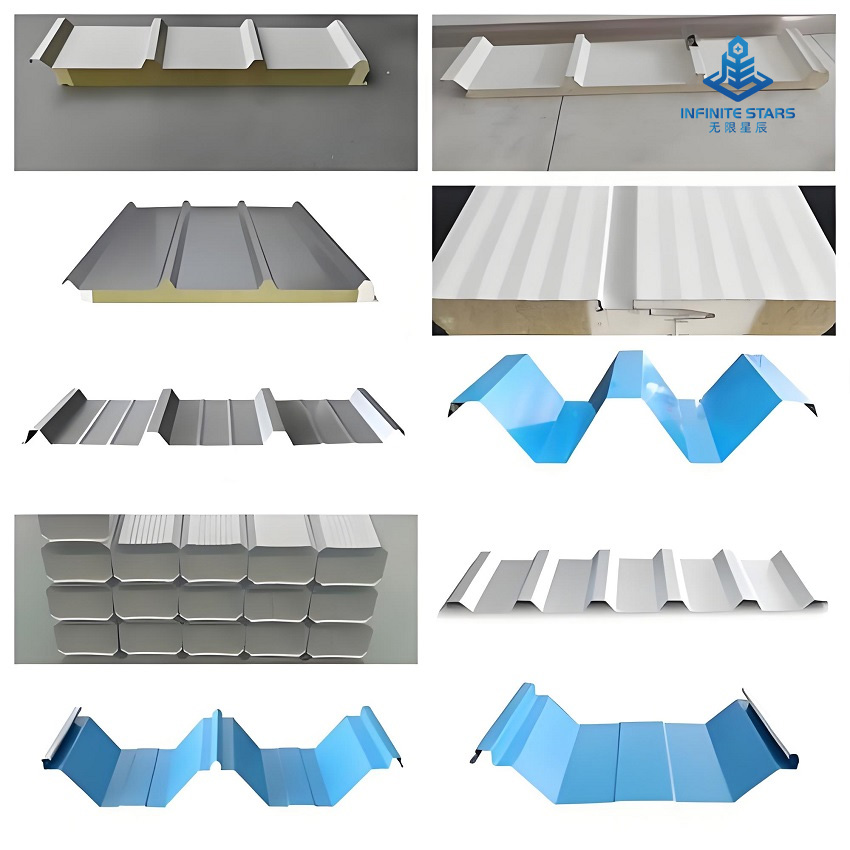

3. Main Types

By Facing Material:

Metal-faced PU panels (most common for factories, warehouses).

Non-metal-faced PU panels (e.g., cleanrooms, labs).

By Application:

Wall panels (vertical load-bearing design).

Roof panels (waterproof drainage structure).

Cold storage panels (thicker, anti-condensation).

4. Applications

Industrial Buildings: Factories, warehouses, logistics centers (energy-saving).

Cold Chain Logistics: Cold storage, refrigerated trucks (insulation + sealing).

Public Buildings: Stadiums, exhibition halls (lightweight large-span roofs).

Cleanrooms: Hospitals, electronics workshops (fireproof + dust-free).

Temporary Structures: Prefabricated houses, construction site enclosures (quick assembly).

5. Pros and Cons

Advantages:

Superior thermal insulation, reducing long-term energy costs.

Lightweight, lowering structural expenses.

Good sound insulation and seismic resistance.

Disadvantages:

Standard PU core has limited high-temperature resistance (improved versions available).

Low-quality products may emit toxic fumes when burned (choose certified products).

6. Purchasing Considerations

Fire Rating: Prioritize B1 or A-rated certified panels.

Core Density: ≥40 kg/m³ for optimal strength.

Panel Coating: Choose PE/PVDF coatings for better weather resistance.

Brand & Certifications: Check ISO, CE, SGS, etc.

7. Popular Brands

Global: Kingspan (Ireland), Metecno (Italy).

China: Xuge,万事达 (WSD), CIMC Group.

PU sandwich panels, with their balanced performance, have become a mainstream choice for energy-efficient and eco-friendly modern construction, especially for projects requiring high insulation and fast installation. Proper selection of fire ratings and structural design is essential for optimal performance.