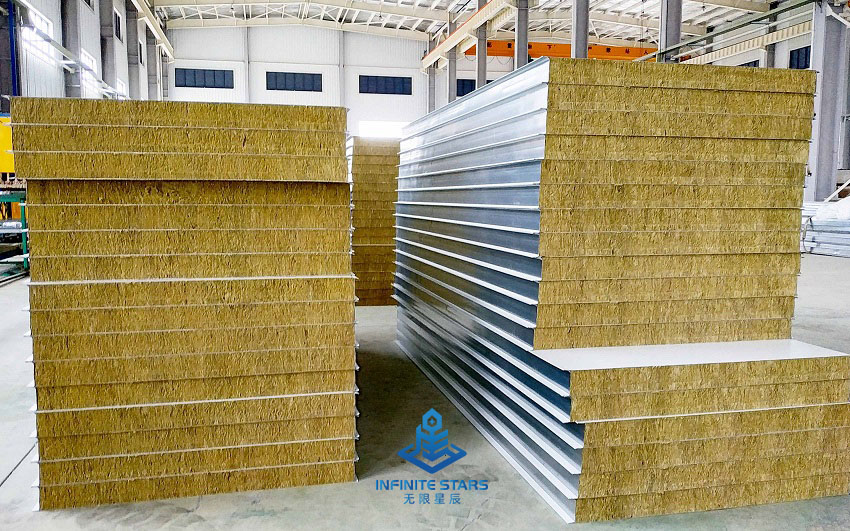

Chinese Manufacturer Of Rock Wool Sandwich Panel

Through automated equipment, the rock wool and steel panels are composited into an integrated unit, revolutionizing the traditional on-site composite method of rock wool panels. While meeting building requirements for thermal insulation, soundproofing, and fire resistance, this achieves superior quality, reliability, and safety.

Key Features:

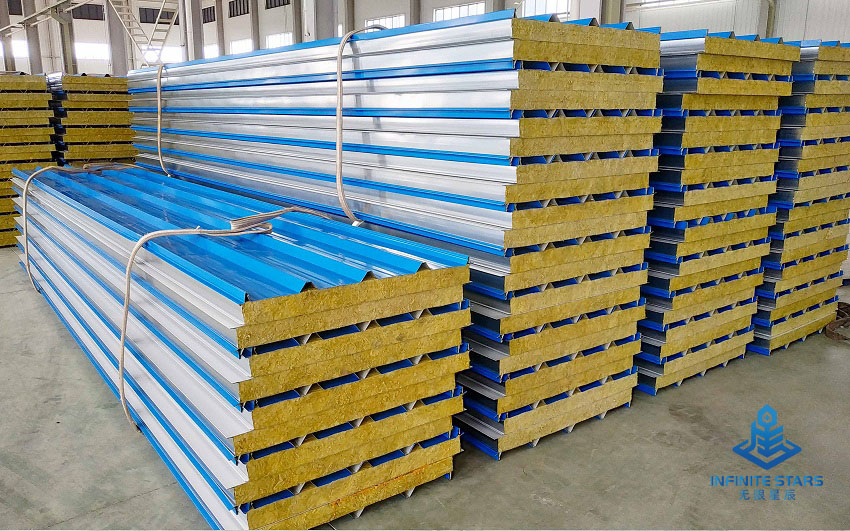

Excellent Rigidity: The rock wool core and dual steel panels bond into a unified structure that works integrally. Combined with the corrugated surface design, the overall rigidity far surpasses that of field-composited profiled panels with rock wool (or fiberglass). When fixed to purlins with connectors, the sandwich panels significantly enhance the roof's overall stiffness and structural performance. This allows for wider purlin spacing, reducing purlin usage by 1/3 to 2/3.

Optimized Interlocking System: The rock wool roof panels feature a snap-lock connection mechanism that eliminates potential leakage at seams while minimizing accessory requirements.

Secure Fastening Method: Specially designed M6 self-tapping screws fix the panels to purlins, providing exceptional resistance against typhoon-level forces. The screws are positioned at crests of the corrugations with specialized waterproof detailing to prevent weak points in water resistance.

Rapid Installation: Eliminating on-site fabrication maintains clean worksites and avoids interference with other trades. The prefabricated nature enables remarkably short installation cycles, with daily progress rates reaching 600-800㎡.