Color Steel Rock Wool Sandwich Panel

Color Steel Rock Wool Sandwich Panel Product Specification

Product Overview

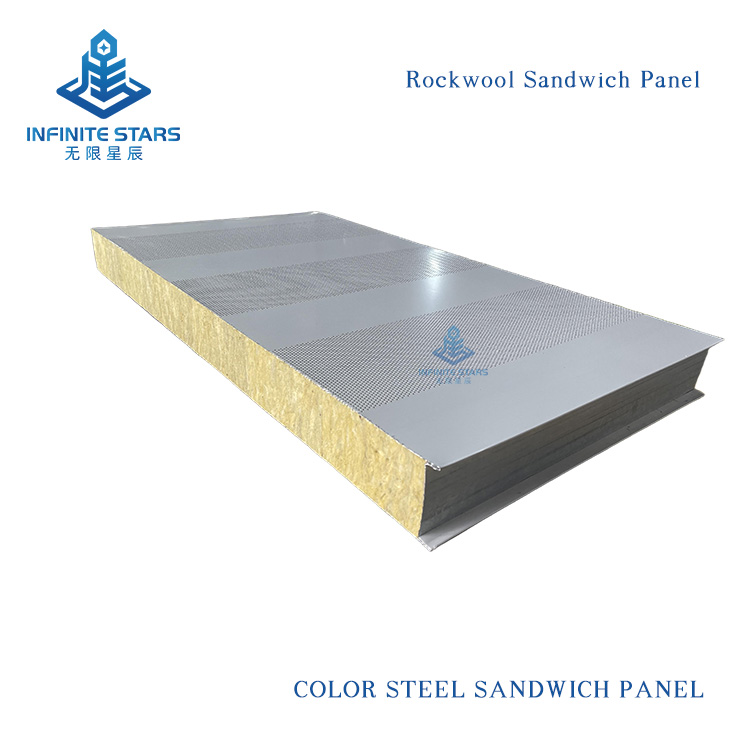

Color steel rock wool sandwich panel is a composite building material consisting of color-coated steel sheets as facing layers and basalt rock wool as the core material, bonded together with high-strength adhesives. Integrating fireproofing, thermal insulation, sound absorption, and decorative functions, it is an ideal enclosure material for modern industrial plants, logistics warehouses, commercial buildings, and other applications.

Product Structure

Facing Layers: Premium color-coated steel sheets (galvanized or galvalume substrate) with polyester (PE), silicon-modified polyester (SMP), or fluorocarbon (PVDF) coatings for superior weather resistance and aesthetics.

Core Material: High-density (≥120kg/m³) basalt rock wool, formed by melting basalt at high temperatures and spinning into fibers, bound with eco-friendly adhesives for uniform fiber distribution.

Bonding Layer: Polyurethane (PUR) or epoxy-based high-strength adhesives ensure permanent bonding between facings and core.

Key Performance Indicators

| Parameter | Value | Test Standard |

|---|---|---|

| Fire Rating | Class A (Non-combustible) | GB 8624-2012 |

| Thermal Conductivity | ≤0.044W/(m·K) | GB/T 10295 |

| Sound Insulation | 28-32dB (100mm thickness) | GB/T 19889.3 |

| Compressive Strength | ≥80kPa | GB/T 13480 |

| Water Repellency | ≥98% | GB/T 10299 |

| Operating Temperature | -40℃~+650℃ | - |

Product Advantages

Exceptional Fire Resistance: Class A non-combustible material, no molten droplets, effectively prevents fire spread.

Durable Thermal Insulation: High closed-cell rock wool structure significantly reduces heat transfer.

Superior Acoustic Performance: Three-dimensional fiber matrix effectively absorbs mid-to-high frequency noise.

Long-Term Durability:

55% aluminum-zinc alloy coating (AZ150) provides 4-6× better corrosion resistance than standard galvanized steel.

Concealed joint design eliminates thermal bridging.

Eco-Friendly: CFCs/HCFCs-free, compliant with LEED green building standards.

Standard Specifications

| Parameter | Range | Remarks |

|---|---|---|

| Thickness | 50-200mm | Customizable in 5mm increments |

| Width | 950-1150mm | Standard: 1000mm |

| Length | ≤12m | Transport limitations |

| Panel Thickness | 0.4-0.8mm | Common: 0.5mm |

| Rib Height | 25-40mm | Selected based on load requirements |

Applications

Industrial Buildings: Electronics factories, pharmaceutical plants, food processing facilities with high cleanliness requirements.

Public Facilities: Airport terminals, high-speed rail stations, stadiums for large-span structures.

Special Environments: Nuclear power plant auxiliary buildings, petrochemical explosion-proof zones.

Retrofit Projects: External insulation for building energy efficiency upgrades.

Installation Guidelines

Use dedicated purlin support systems with spacing ≤1.5m.

Apply weather-resistant sealant to panel joints.

Use metal-specific cutting tools with proper PPE for fabrication.

Store panels elevated to avoid water immersion.

Quality Assurance

10-year material warranty.

ISO 9001/14001 certified.

Complies with EN 13501-1 fire standards.

Third-party test reports available (SGS, BV, etc.).

Service Support

Free load calculation and structural design consultation.

CAD/BIM detailing services.

48-hour nationwide emergency response.

Note: Custom upgrades available:

Anti-static coating (surface resistance: 10⁶-10⁹Ω).

Aluminum foil reflective layer (enhanced summer heat insulation).

Special-shaped components (curved panels, corner pieces, etc.).